Group info

COB vs SMD LED Strip -Which is Best for Your Home?

- date: 2024-07-04

- category: Industry news

- click:

With LED light strips becoming a popular choice for modern home decoration and commercial space design. But few people know about COB vs SMD LED Strip type? Which is best for your home? Please read on to learn more about COB vs SMD LED Strip to ensure that you have the right product for your needs.

Here we introduce you to COB vs SMD LED strip types:

1. COB - Chip on Board LED Light Strip

2. SMD - Surface Mount Diode LED Light Strip

COB - Chip on Board LED Light Strip

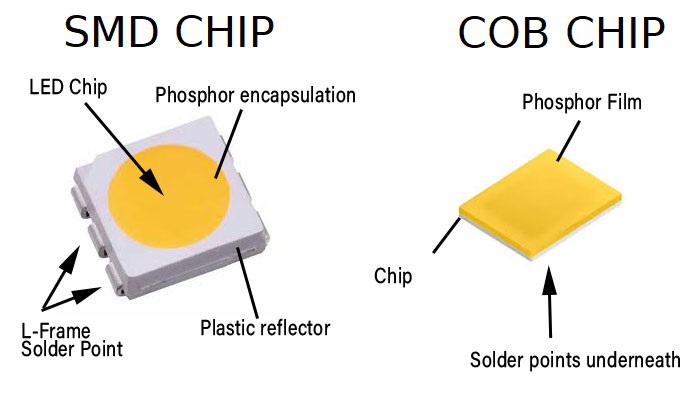

COB light strip is a kind of LED light strip using COB (Chip on Board) technology. There is a printed circuit board on the substrate of COB, and the diode chips are arranged in parallel or series according to the PCB circuit. The substrate can be an aluminum substrate or a ceramic substrate. The ceramic substrate has better thermal conductivity and can ensure a lower LED operating temperature. Although COB LED integrates various chips on one substrate, it only has two metal connection points: anode and cathode. This technology is not distributed on the surface of the PCB like LED light strips.

The advantages of LED COB strips are their high brightness, high uniformity and good color reproduction, which can provide softer and more natural lighting effects.

SMD - Surface Mounted Diode LED Light Strip

LED SMD light strips are surface mounted devices (Surface Mounted Devices) light strips. They are a common type of LED light strips. They are directly mounted on the substrate of the light strip, and rows of small lamp beads are formed after packaging.

SMD LED chips come in a variety of sizes: 2835, 3030, 3014, 5050, 5630; they are named according to their size: length and width. For example, the size of 2835 is 2.8 x 3.5 mm, the size of 3030 is 3.0 x 3.0 mm, the size of 3014 is 3.5 x 2.8 mm, the size of 5050 is 5.0 x 5.0 mm, and the size of 5630 is 5.6 x 3.0 mm. SMD chips are small and close to the design of flat square computer chips.

SMD light strips are usually flexible, thin, power-saving, and have a long life. The main function of SMD light strips is to provide basic lighting and decorative effects. It can choose different colors, brightness, and color temperature according to different needs and scenes to achieve different lighting effects, such as soft atmosphere lighting, emphasized accent lighting, and dazzling decorative lighting, etc.

COB vs SMD LED Strip

1.Different processes. SMD is to fix the LED chip on the bracket, make electrical connections through gold or copper wires, and then use epoxy resin for protection; COB is to solder the LED chip directly on the PCB board, and no longer need brackets and reflow soldering.

2. Different costs. SMD is relatively complex in production process and has low cost, which is suitable for a variety of application scenarios; COB has higher cost due to its higher integration and more complex production process, and is mainly concentrated in the field of small-pitch LED display.

3. Different performance. The LED lamp beads produced by SMD are smaller in size, and the brightness of a single bead is lower, and usually multiple beads need to be used in combination; the LED lamp beads produced by COB are larger in size, can provide high brightness output, and have better color rendering and heat dissipation performance.

4.Different applications. SMD is suitable for a variety of application scenarios, such as outdoor and indoor display screens; COB is mainly used in the field of small-pitch LED display.

5. Different stability. SMD has a higher rate of dead lights and the risk of falling lights due to its exposed lamp beads; COB has better stability due to its high integration and welding method.

6. Different maintenance. SMD is easy to repair on site because the lamp beads can be replaced individually; COB may need to be returned to the factory for repair due to its high integration.

Summary: Both SMD and COB have a wide range of applications, but SMD is relatively customized and can meet a variety of lamps. However, you can choose between SMD or COB types based on your needs for energy efficiency and versatility.